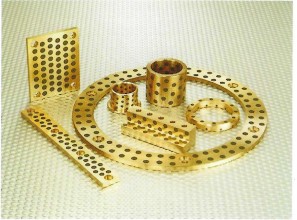

Self-lubricating Bearings and Self-lubricating Rings and Slide

Self-lubricating bearings and self-lubricating rings.

Self-lubricating bearings are a specialized type of bearings that have the ability to provide lubrication without the need for external lubricants. These bearings are typically made from materials with inherent lubricating properties, such as bronze, steel, or polymers. They release small amounts of solid or liquid lubricants during operation, forming a thin film that reduces friction and wear on the bearing surfaces. Self-lubricating bearings are commonly used in applications where high speeds, high temperatures, or the absence of external lubrication make traditional bearings impractical, such as automotive engines, machinery, and equipment.

Self-lubricating rings are ring-shaped structures that possess self-lubricating capabilities. They are often made from materials with excellent lubricating properties, such as polymers or metal composites. Inside the self-lubricating rings, solid or liquid lubricants are embedded, and when the rings come into contact with other components or surfaces, the lubricants are gradually released, forming a lubricating layer that reduces friction and wear. Self-lubricating rings are commonly used in applications such as bearings, seals, and rotating connections, offering long-lasting lubrication performance and reducing maintenance requirements.

The advantages of self-lubricating bearings and self-lubricating rings include consistent and long-term lubrication performance, reduced energy loss, extended component life, lower maintenance requirements, and improved operational efficiency. However, their performance is still influenced by factors such as load, speed, temperature, and environment. When selecting and applying self-lubricating bearings and self-lubricating rings, it is important to evaluate and test them based on specific requirements to ensure optimal performance and durable lubrication effects.